Post by krwada on Jul 4, 2014 15:42:04 GMT -5

OK ... I know that most of you have been following my Custom 1022 build thread. As far as accuracy ... it is pretty darned good.

However, just having accuracy does not mean that the thing works. The firearm must not only be accurate, but 1st and foremost, it must be SAFE and RELIABLE in operation! Without the safety and reliability ... the firearm becomes a useless piece of dangerous metal ... no matter how accurate the thing is.

So, I fully tested the thing using action proving dummy rounds before I go to the range. The action proving dummy rounds cycled great. I loaded up a full 10 round mag, cycled the thing and the rounds went in and ejected cleanly. Then, I take the firearm out to the range ... and I cycle the first round ... and it works great. However ... I noticed that I have to push the bolt by about 1/16" of an inch to get the bolt to go into full battery. I fire the round and it appears to cycle ... only I cannot fire the next round. I push the bolt again ... and it engages ... pull the trigger, and the round goes off. I do this several times ... all the while pushing the bolt in to engage the next round. I also notice that several rounds do properly fully engage into battery. All during this time, I am thinking that maybe the problem is with not honing the extractor or maybe the bolt needs to be worked into the receiver. The thing seemed to operate much better after sending a few dozen rounds down range.

So ... after sighting the thing in ... and noting that the action seems to be working much better. I decide to try a careful experiment with the firearm pointed downrange.

I drop the magazine with a live round in the chamber. Carefully point the thing down range. Pull the bolt back, release ... and I get a slam fire! Well, after regaining my composure and just about crapping my pants ... I check to see that there are no rounds in the barrel, remove the mag, put the firearm away and head on home.

So ... I take the thing apart and inspect the bolt using one of the dummy action proving rounds. This is what I saw:

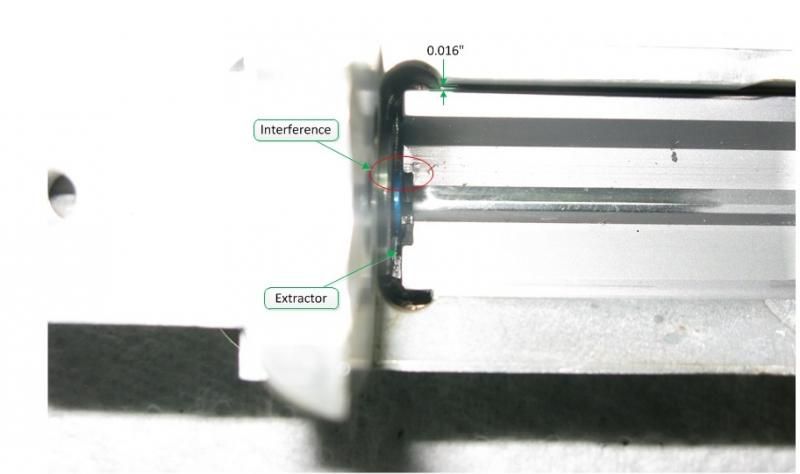

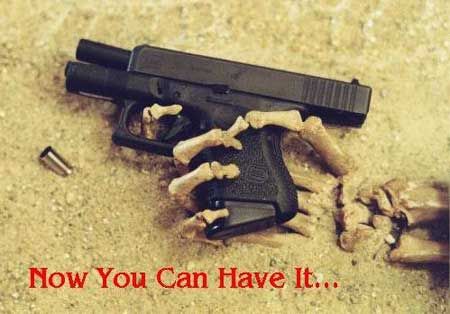

Now, if you lean forward towards your monitor, and squint at this picture, you can clearly see that the bolt face and primer pocket, away from the charging handle just barely contacts the rim of the ammunition. This is definitely not good. One of the things I noticed was that there is a gap between the bolt and the receiver away from the charging handle.

If I place some pressure on the bolt through the ejector port, everything lines up such that there is no interference with the primer pocket and the rim of the cartridge. I take out my feeler gauge and measure the gap at 0.016".

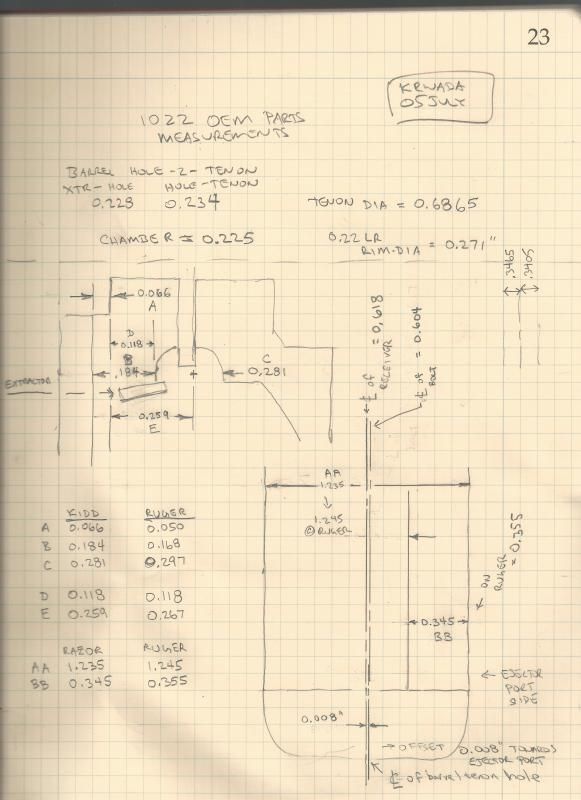

I did measure the barrel hole and it is dead on center. I also went to the Ruger Forum, and Rimfire Central, and have found other folks who are having the same problem with the Select Fire RAZOR-1022 blank receiver. I have also read all of the suggestions in those forums, and have found that almost ALL of them recommend fixes that in my opinion are either unsound or unsafe or both.

I believe the only recourse to fixing this is to order another blank and properly machine the barrel hole to custom fit the bolt position in the receiver. The downside to this approach is that it will be a full custom fit to a specific bolt ... (Kidd in this case). I believe this is a small price to pay to get a proper functioning and SAFE operating firearm.

I have been emailing Phil Camarda over at Select Fire. He tells me that, when properly machined according to directions his receivers will have a drop in fit using the standard Ruger OEM bolt. I told him about the off-center bolt to barrel relationship. He told me that there are many variances of all the OEM parts out there, and that even the hole on the barrel in some cases may not be fully centered. I find this difficult to believe with the barrel I purchased. This is because I purchased a quality Volquartsen barrel. Scott Volquartsen is well know in competition circles to make and produce very high quality parts.

I got the new blank and confirmed that all the internal dimensions are in exact accordance with the previous blank I machined. I also noticed that some of the radiuses are different. This difference should allow the trigger group to fit a bit better than the previous blank I purchased.

Most likely, I will machine the barrel hole 0.015" off center towards the ejector port of the receiver.This should properly line up the chamber to the bolt face.

However, just having accuracy does not mean that the thing works. The firearm must not only be accurate, but 1st and foremost, it must be SAFE and RELIABLE in operation! Without the safety and reliability ... the firearm becomes a useless piece of dangerous metal ... no matter how accurate the thing is.

So, I fully tested the thing using action proving dummy rounds before I go to the range. The action proving dummy rounds cycled great. I loaded up a full 10 round mag, cycled the thing and the rounds went in and ejected cleanly. Then, I take the firearm out to the range ... and I cycle the first round ... and it works great. However ... I noticed that I have to push the bolt by about 1/16" of an inch to get the bolt to go into full battery. I fire the round and it appears to cycle ... only I cannot fire the next round. I push the bolt again ... and it engages ... pull the trigger, and the round goes off. I do this several times ... all the while pushing the bolt in to engage the next round. I also notice that several rounds do properly fully engage into battery. All during this time, I am thinking that maybe the problem is with not honing the extractor or maybe the bolt needs to be worked into the receiver. The thing seemed to operate much better after sending a few dozen rounds down range.

So ... after sighting the thing in ... and noting that the action seems to be working much better. I decide to try a careful experiment with the firearm pointed downrange.

I drop the magazine with a live round in the chamber. Carefully point the thing down range. Pull the bolt back, release ... and I get a slam fire! Well, after regaining my composure and just about crapping my pants ... I check to see that there are no rounds in the barrel, remove the mag, put the firearm away and head on home.

So ... I take the thing apart and inspect the bolt using one of the dummy action proving rounds. This is what I saw:

Now, if you lean forward towards your monitor, and squint at this picture, you can clearly see that the bolt face and primer pocket, away from the charging handle just barely contacts the rim of the ammunition. This is definitely not good. One of the things I noticed was that there is a gap between the bolt and the receiver away from the charging handle.

If I place some pressure on the bolt through the ejector port, everything lines up such that there is no interference with the primer pocket and the rim of the cartridge. I take out my feeler gauge and measure the gap at 0.016".

I did measure the barrel hole and it is dead on center. I also went to the Ruger Forum, and Rimfire Central, and have found other folks who are having the same problem with the Select Fire RAZOR-1022 blank receiver. I have also read all of the suggestions in those forums, and have found that almost ALL of them recommend fixes that in my opinion are either unsound or unsafe or both.

I believe the only recourse to fixing this is to order another blank and properly machine the barrel hole to custom fit the bolt position in the receiver. The downside to this approach is that it will be a full custom fit to a specific bolt ... (Kidd in this case). I believe this is a small price to pay to get a proper functioning and SAFE operating firearm.

I have been emailing Phil Camarda over at Select Fire. He tells me that, when properly machined according to directions his receivers will have a drop in fit using the standard Ruger OEM bolt. I told him about the off-center bolt to barrel relationship. He told me that there are many variances of all the OEM parts out there, and that even the hole on the barrel in some cases may not be fully centered. I find this difficult to believe with the barrel I purchased. This is because I purchased a quality Volquartsen barrel. Scott Volquartsen is well know in competition circles to make and produce very high quality parts.

I got the new blank and confirmed that all the internal dimensions are in exact accordance with the previous blank I machined. I also noticed that some of the radiuses are different. This difference should allow the trigger group to fit a bit better than the previous blank I purchased.

Most likely, I will machine the barrel hole 0.015" off center towards the ejector port of the receiver.This should properly line up the chamber to the bolt face.

My daughter came from Missouri, my son and grand son, my wife and I had a nice dinner of grilled "porter house" pork chops, corn on the cobb, my son, G'son and I share 10/5. G'son is 4 minutes early though @ 10/4.

My daughter came from Missouri, my son and grand son, my wife and I had a nice dinner of grilled "porter house" pork chops, corn on the cobb, my son, G'son and I share 10/5. G'son is 4 minutes early though @ 10/4.

Pooh I hope you find to right house .

Pooh I hope you find to right house .