hal8337

Member

Posts: 89  Location: Livonia, Louisiana

Location: Livonia, Louisiana

|

Post by hal8337 on Sept 21, 2015 7:28:20 GMT -5

I have never annealed any brass for reloading but that is about to change. I have been loading more and shooting more which converts to working my brass more. I have researched the web for info. and used the advice of some of you on this site to put together the tools to do this correctly. I am currently waiting on some tempilaq 750 to arrive so I can start. I have used old brass to practice with so I don't have to experience any difficulties on my good brass. If any of you would like to share any of your experiences (do's & don'ts) I would sure appreciate it. Thanks

|

|

7mmmountaineer

Member

Time to face it I am a workaholic............

Posts: 521

|

Post by 7mmmountaineer on Sept 25, 2015 17:22:44 GMT -5

Hal would this be the 30-06 Hornady brass you bought a while back? If so with it being a standard caliber I would anneal every third or fourth firing with a magnum every other firing and anneal before you resize. From the time I started annealing till just a couple months ago I annealed as my final brass prep step but Dan advised me to anneal before resizing. It dose truly make a difference as it shaved about .15 off my average group size from my old way of doing it.

|

|

hal8337

Member

Posts: 89  Location: Livonia, Louisiana

Location: Livonia, Louisiana

|

Post by hal8337 on Sept 26, 2015 8:15:51 GMT -5

I am reloading 223,243,260 & 30-06. The 260 Remington has showed the most neck wear/damage. Your suggestion for every 3rd to 4th sounds good to me. I read that post where Dan suggested to anneal before sizing so that is also in my guidelines for annealing. Is the neck area the most critical area or is it a combination of the neck/shoulder? I ran a batch yesterday and centered mostly on the neck because of the way I positioned my propane torches. From some video's I viewed it shows heat traveling down the case body a small amount past the shoulder/body. Most to all of the one's I did yesterday are only centered on the neck. When the tempilaq turned to liquid I dropped the case into a bucket. If I need to concentrate on both the neck/shoulder I can adjust the torch angle. From the signs of heat (color) on the cases I did I am not worried about over heating the case head area. Thanks for the info.

|

|

7mmmountaineer

Member

Time to face it I am a workaholic............

Posts: 521

|

Post by 7mmmountaineer on Sept 26, 2015 10:37:43 GMT -5

Hal Dan might tell you different but I do try to catch the shoulder area also. Dan has also pointed out that once the damage is started no amount of annealing will repair the damage just slow it's progress beyond the point you started annealing. I do keep some older brass on hand for just plinking rounds or just fun shooting but I do not really use it all that often. I replaced most of my brass when I started annealing and keep them separated into batches with notes in the container with how many rounds fired since last annealing.

|

|

hal8337

Member

Posts: 89  Location: Livonia, Louisiana

Location: Livonia, Louisiana

|

Post by hal8337 on Sept 26, 2015 12:22:43 GMT -5

That sounds like good advice to start fresh. Thanks  |

|

|

|

Post by hacker54 on Sept 28, 2015 18:58:17 GMT -5

hal, What for setup are you using to do yours. Home made or a commercial one? I have done some web searching and found one for about $100 +/- so so. I found this out fit and will inform my son-in-law as I am the one loading for his AR as of now. Told him after so many loadings the brass will need to be annealed or buy new. www.cartridgeanneal.com/home.html |

|

hal8337

Member

Posts: 89  Location: Livonia, Louisiana

Location: Livonia, Louisiana

|

Post by hal8337 on Sept 29, 2015 6:46:34 GMT -5

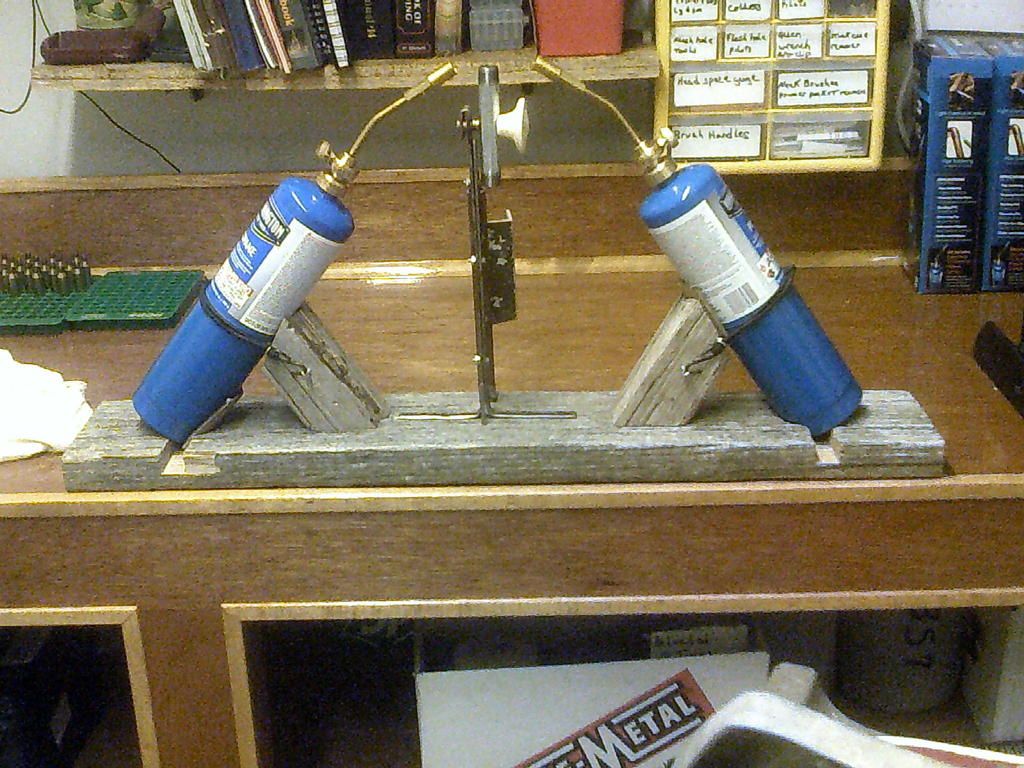

This is my version of the one you posted on your link with a few variances but it works. Mine is based off longer propane bottles than the one shown on the link. I saw a video of a gentlemen that made one real close to the one on your link and he paid 15 dollars for all the parts w/o the propane torches. I only bought 2 each 3/8" x 4" pipe nipples. The rest I had laying around in my shop. Inside the center of the pipe is a wooden doll which helps to place the cartridges at the correct height so the torch flame is in the correct place. If you look close enough you can see pieces of card board to shim the bottles to get the correct flame position. When I was growing up I did frame carpentry work and not trim. To do different length cases you would only need another pipe to fit the case and a wooden doll long enough to position it correctly. I have one pipe for 243 & 260 and another for 270 & 30-06. I applied some tempilaq 750 on the inside of the case neck and faced it towards me so it is easy to see it melt when the temperature reaches 750.

|

|

|

|

Post by hacker54 on Sept 29, 2015 20:34:14 GMT -5

hal,

Thanks for showing the photo. This will give me a way of making my own. Looking over that link I posted and seeing what this guy had it made me think of making one and seeing yours was a help with that.

|

|

dangun

Member

I love the smell of burnt gun powder.

Posts: 517

Location: SW Florida

|

Post by dangun on Oct 7, 2015 22:12:40 GMT -5

I'm late to the party but you do want to anneal the shoulder. I try to center the flame so that it is at the base of the neck. That way you get the neck and shoulder. I would also dump the cases into a bucket of water. That will insure the head doesn't get to hot.

|

|

hal8337

Member

Posts: 89  Location: Livonia, Louisiana

Location: Livonia, Louisiana

|

Post by hal8337 on Oct 8, 2015 6:22:50 GMT -5

Thanks Gentlemen

I have annealed 2 - 20 ea batches successfully and have incorporated your comments into my annealing process. Using the tempilaq really takes the guess work out of it. I have a son-in-law that loves to shoot which gives me plenty practice with all my reloading skills so the annealing should get to be second hand before long. Thanks again

|

|

|

|

Post by lexusmgr on Sept 29, 2016 20:48:42 GMT -5

I don't have a fancy setup for annealing, but I regularly do 308, 30-06 and 303 British. What I do is set the temperature on the lead to 750°. Then, using heavy gloves, i dip the brass into the pot. I count to three, and remove. I can do 100 in a matter of minutes. It is fast and does not require any additional equipment or spenditure on my part.(Yes, I'm cheap)

So if you cast, try it.

I have a Lee bottom pour pot. Guess you could say is a dual purpose pot. Casting and annealing.

|

|

|

|

Post by hacker54 on Oct 1, 2016 18:21:44 GMT -5

Lex,

I have read some place to use your lead melting pot to do as you do. Those people that did had according to them very good results. Item on my list of things I need is a casting thermometer.

|

|

|

|

Post by lexusmgr on Oct 1, 2016 23:03:03 GMT -5

Hello Hacker

Yes, definitely a very useful tool! I should have mentioned that I set the lead temperature to 750 using the thermometer. That is supposed to be the optimal temp for annealing brass. I learned this many, many years ago, but since I didn't have the equipment, didn't start doing it until 4 years ago.

Hope some of the other fellows try it and pass it along.

Regards

Lex

|

|

|

|

Post by wychild on Oct 17, 2016 17:05:53 GMT -5

I have been using this method for years and found it the most efficient. I mark each case 1/8" past the shoulder so that each is dipped the same.

I had used a thermal couple to measure the case when I first started to make sure I didn't heat the case to much above the kneck, but after doing many cases, I found that if I held the case with a pare of pliers and dipped the case for 4 seconds then in water just the neck and shoulder were annealed. 750deg is the optimum temp for the lead.

One other check I do when I have reloaded the cases many times and before I anneal them. is to take a piece of wire bend it at a 90deg angle in one end about a quarter inch long. then cut it at anangle across so the point is sharp. I use this by inserting the wire in the case till it hits the base and draging it up the inside wall, in doing this I can feel if the case is being cut at the base if you can feel it disgaurd the case.

|

|

poohzilla

Member

Give me a place to stand and a long-enough lever, and I will invariably break the lever.

Posts: 1,050  Location: New Hamster

Location: New Hamster

|

Post by poohzilla on Oct 17, 2016 19:28:20 GMT -5

Wy, good to hear from you !

|

|

bob

Member

I'm too old to be nice but never too old to learn!

Posts: 1,457  Location: Northern California

Location: Northern California

|

Post by bob on Oct 17, 2016 21:52:17 GMT -5

Wychild, good to hear from you. I know it has been a little sleepy around here but say hello once in awhile.

|

|

|

|

Post by wychild on Oct 17, 2016 22:27:35 GMT -5

Thanks for the welcome I know I have been a little shy lately but its been a ruff few years 4 major operations in the last 4 years.I am get up on face book a bit and sometimes on Cheyenne shooters blog check it out you can use your same Id and password

|

|

gws

Member

Posts: 969

Location: NW New Mexico

|

Post by gws on Oct 18, 2016 10:19:27 GMT -5

Great to see you survived the Doctors and Hospitals. 4 times in 4 years is playing with shaky odds.....glad you've beat them!! My latest is rotator cuff surgery 4 weeks ago....I really messed things up so they had to make a 4" long incision on the front and 2 arthroscopic ones in the back. Not terribly serious, just painful....and I sure as hell can't shoot.  Gettin old ain't for sissies. |

|

|

|

Post by wychild on Oct 18, 2016 10:48:37 GMT -5

I know hat you mean I had my left shoulders rotator cuff worked on a number of years ago and you are correct this getting old keeps get tin in my way. If I have any more parts replaced they are going to call me the bionic man.

|

|